We work proudly alongside some of the biggest names from remarkable industries around the world.

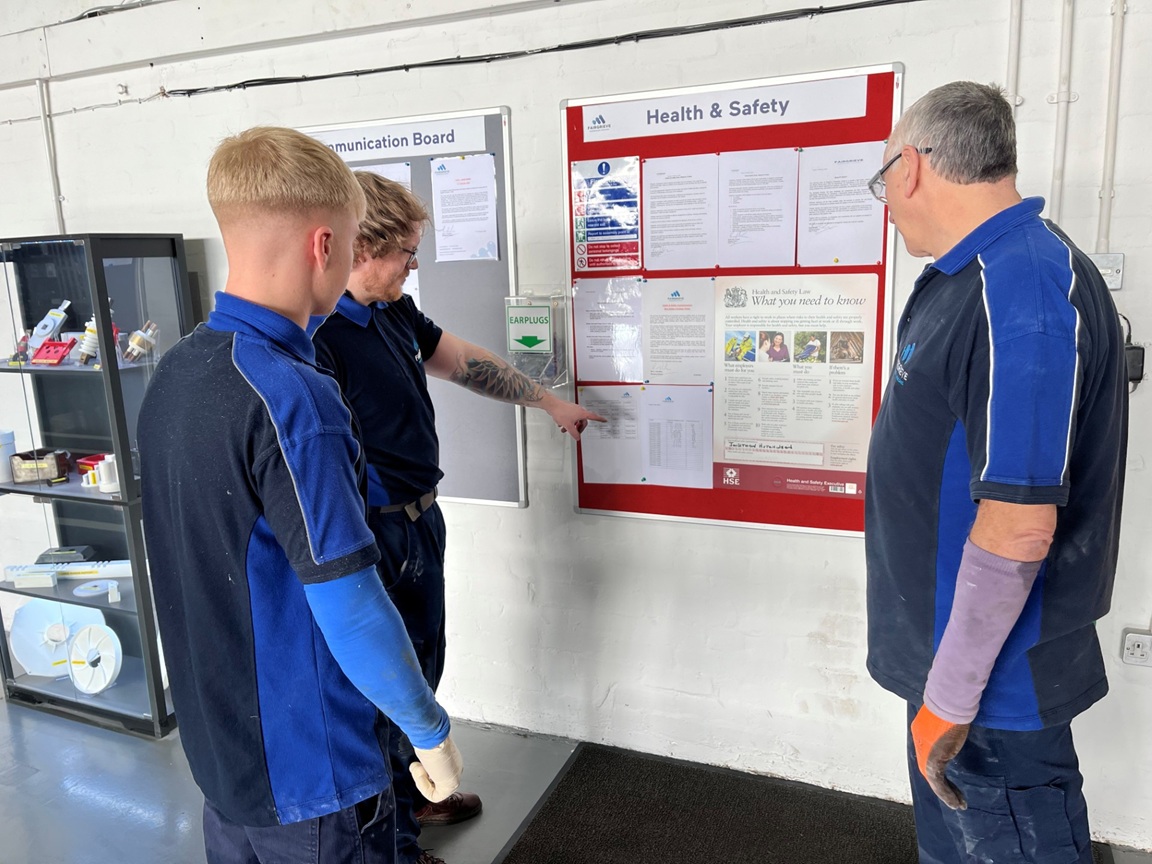

A ‘complete commitment to working to the highest standards’ at Fairgrieve Compression Moulding has helped the business surpass five years without a single recorded accident on site.

The business has won high praise from British Standards Institute and their expert consultant Michael Collier, who has worked alongside the team for the past four years.

In that time, Mr Collier, of KBC Ltd, has also helped Fairgrieves secure three ISO accreditations – globally recognised standards for quality, environmental, safety and health.

Mr. Collier’s expertise was brought in to support Fairgrieves in 2021 by managing director Barry Davidson, who had recently joined the business and was looking to transform its working practices and policies.

Now, having recently sailed through a BSI ‘surveillance audit’ of its ISO 9001, ISO 14001 and ISO 45001 accreditations, and passed five years without a work accident, Mr Collier says Fairgrieves is a great example to others.

100% commitment of team

“Fairgrieves has a great safety record and I have to say that it has been achieved because the entire team has been 100% committed to establishing an organised, safe, efficient working environment and they have been totally engaged in continuous improvement since I started working with them,” said Mr Collier.

With the business using machinery and tools weighing several tonnes day-to-day, and processes to form plastics involving extremely high temperatures, Mr Collier says thorough risk assessments are required, and safety processes which must be followed religiously each and every time without fail.

“There’s great discipline throughout the team at Fairgrieves to follow process, and the importance of that can’t be underestimated,” he said.

“We have thorough risk assessments for each process and piece of machinery, and we have ensured that staff have benefitted from extensive, tailored training, from toolbox talks to specific courses.

“The team on the factory floor follow specific procedures for carrying out pre-operative checks of the machinery they use each and every time, they ensure they fill in documentation, and the production manager oversees this also every day.

“At the end of each day, machines are cleaned, as are all areas of the factory, to ensure all is in full working order and ready to start again, safely, the following day,”

An example to other businesses

Mr Collier says Fairgrieves is now an example to other businesses when it comes to developing a culture of quality, environmental good practice, safety and efficiency.

“The leadership team of Barry Davidson, Dawn Stavers and Johnathon Hutchinson ensure standards never drop,” he added.

“The business has annual ISO assessments, and then strategic reviews which come around every three years. Next year, and I foresee no issue with passing those again. These things are not seen as tasks any more, it’s just what they do day to day. There’s a complete commitment to working to the highest standards.”

Managing Director Barry Davidson said: “We are thrilled to have surpassed five years without a single recorded accident on site, particularly given the nature of our work.

“Michael has had a hugely positive impact on our business and our working procedures. We’re proud to not only be a great place to work, but a safe place to work. The entire team can be proud of our record.”